Special Applications Graphics Machines, Continued

Engraver

Manual engravers may be hand-driven or motorized. Newer, automated

features

engravers have keyboards, a memory system, and an editing screen.

Engravers enlarge, reduce, or create the same-size letters by tracing fonts

secured in a galley and redrawing that image into plastic or metal. Engravers

have a motor, pulleys, a galley tray, a tracing point, tracing arms, and jigs to

hold round or flat objects. Templates are slid into a galley tray and secured

by thumbscrews. Templates are available in many styles and are made of

brass. The engraver cuts the letter/symbol outline into plastic or metal, using

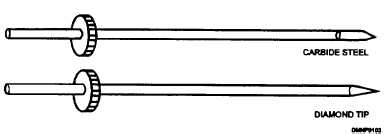

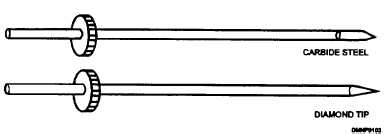

a cutter. Cutters are carbide steel for cutting plastic and diamond-tipped for

engraving metal. Use the motor with the carbide cutters. The diamond-

tipped cutters require only hand pressure to cut metal.

Figure 4-12 shows different cutter points.

Figure 4-12. —Cutter profiles.

General care

Inspect the engraving machine before using it. Like other electrically

powered tools, inspect the cords and wiring for wear. Examine the pulleys

and belts for dryness and stretching. Use sharp cutters of the correct depth

in the machine.

General

Clean debris from all surfaces. Remove the jigs to brush away debris under

maintenance

the galley. Remove the thumbscrews and brush debris from the galley trays.

Brush away debris from under the jigs and surrounding areas. Engraving

residue is similar to sawdust; it gets everywhere. Maintain sharp cutter

points and clean, sharp templates. Do not over tighten thumbscrew settings.

Continued on next page

4-28