Process and Copy Cameras, Continued

Sheet film and

Sheet films and papers can be developed conventionally in a four-tray manual

print

process or with an automatic processor.

development

Four-tray

Conventional development of photographic sheet films and papers is a four-

development

tray process. The first tray contains developer. Developer is a chemical that

reacts with the film or paper to make images appear. The second tray

contains stop bath, a weak acetic acid that neutralizes the action of the

developer. The third tray contains fixing agent. The fixer stabilizes the

developed image by chemically removing undeveloped light-sensitive

crystals. The fourth tray contains water. Water removes chemicals from the

film or paper. Allow films or papers to thoroughly rinse in water after

development. If the water wash is insufficient, the film or paper continues to

chemically change resulting in uneven streaking or browness.

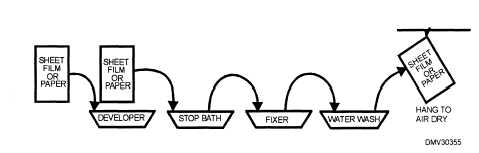

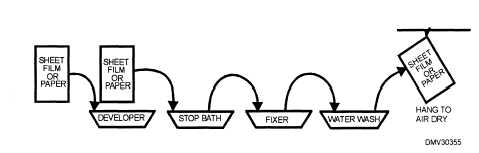

Figure 7-5 illustrates the process for conventional development of sheet films

and papers.

Figure 7-5.—Conventional development of sheet films and papers.

The temperature of each tray’s contents should be approximately 70 degrees.

Temperature variation between trays should not exceed 5 degrees. The

warmer the liquids in the trays, the faster action takes place. The

disadvantage of excessively warm temperatures is rapid overdevelopment.

The disadvantages of cooler than required temperatures is slow development

and weak images. Extreme temperature variations cause increased grain or

reticulation. Do not put your hands into the chemicals. The warmth of your

hands will raise the temperature of the solutions. Moving your hand from

one tray to another will contaminate them. Use tongs to move the film or

paper through the development process. Hang films and papers by one

corner to air dry.

Continued on next page

7-11