CHAPTER 4

MACHINE DRAWING

When you have read and understood this chapter,

you should be able to answer the following learning

objectives:

Describe basic machine drawings.

Describe the types of machine threads.

Describe gear and helical spring nomenclature.

Explain the use of finish marks on drawings.

This chapter discusses the common terms, tools,

and conventions used in the production of machine

drawings.

COMMON TERMS AND SYMBOLS

In learning to read machine drawings, you must first

become familiar with the common terms, symbols, and

conventions defined and discussed in the following

paragraphs.

GENERAL TERMS

The following paragraphs cover the common terms

most used in all aspects of machine drawings.

Tolerances

Engineers realize that absolute accuracy is

impossible, so they figure how much variation is

permissible. This allowance is known as tolerance. It

is stated on a drawing as (plus or minus) a certain

amount, either by a fraction or decimal. Limits are the

maximum and/or minimum values prescribed for a

specific dimension, while tolerance represents the total

amount by which a specific dimension may vary.

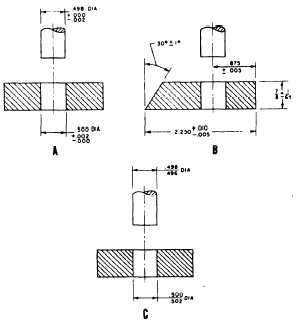

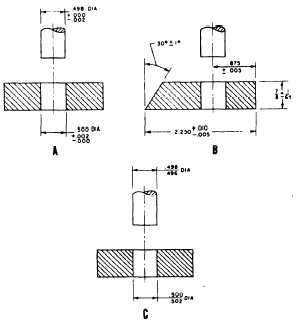

Tolerances may be shown on drawings by several

different methods; figure 4-1 shows three examples.

The unilateral method (view A) is used when variation

from the design size is permissible in one direction only.

In the bilateral method (view B), the dimension figure

shows the plus or minus variation that is acceptable. In

the limit dimensioning method (view C), the maximum

and minimum measurements are both stated

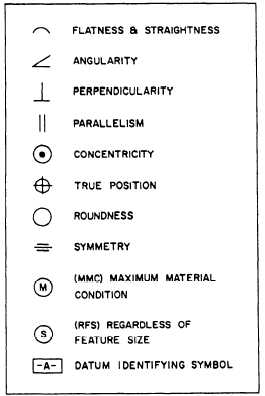

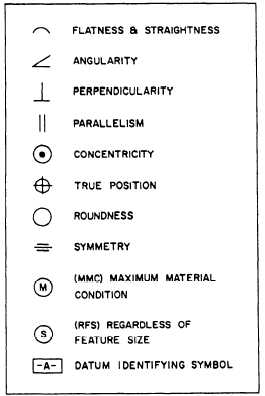

The surfaces being toleranced have geometrical

characteristics such as roundness, or perpendicularity to

another surface. Figure 4-2 shows typical geometrical

characteristic symbols. A datum is a surface, line, or

Figure 4-1.—Methods of indicating tolerance.

Figure 4-2.—Geometric characteristic symbols.

4-1