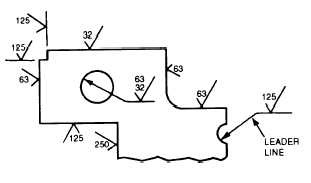

which it refers. If space is limited, the symbol may be

placed on an extension line on that surface or on the tail

of a leader with an arrow touching that surface as shown

in figure 4-18.

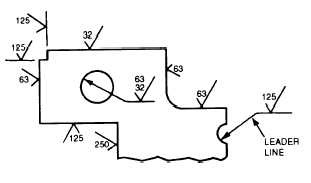

When a part is to be finished to the same roughness

all over, a note on the drawing will include the direction

“finish all over” along the finish mark and the proper

number. An example is FINISH ALL OVER32. When

a part is to be finished all over but a few surfaces vary

in roughness, the surface roughness symbol number or

numbers are applied to the lines representing these

surfaces and a note on the drawing will include the

surface roughness symbol for the rest of the surfaces.

For example, ALL OVER EXCEPT AS NOTED (fig.

4-19).

Figure 4-18.—Methods of placing surface roughness symbols.

STANDARDS

American industry has adopted a new standard,

Geometrical Dimensioning and Tolerancing, ANSI

Y14.5M-1982. This standard is used in all blueprint

production whether the print is drawn by a human hand

or by computer-aided drawing (CAD) equipment. It

standardizes the production of prints from the simplist

hand-made job on site to single or multiple-run items

produced in a machine shop with computer-aided

manufacturing (CAM) which we explained in chapter

2. DOD is now adopting this standard For further

information, refer to ANSI Y14.5M-1982 and to

Introduction to Geometrical Dimensioning and

Tolerancing, Lowell W. Foster, National Tooling and

Machining Association, Fort Washington, MD, 1986.

The following military standards contain most of

the information on symbols, conventions, tolerances,

and abbreviations used in shop or working drawings:

ANSI Y14.5M-1982

Dimensioning and Tolerancing

MIL-STD-9A

Screw Thread Conventions and

Methods of Specifying

ANSI 46.1

MIL-STD-12,C

Surface Texture

Abbreviations for Use On Drawings

and In Technical-Type Publications

FIgure 4-19.—Typical examples of symbol use.

4-7