5.

6.

7.

8.

the 2-4 means the weld should be 2 inches long

(L) with a center spacing or pitch (P) of 4 inches.

This shows the supplementary symbols. This

supplementary symbol means the weld should

be convex.

This shows the finish symbol, G, which means

the weld should be finished by grinding. Note

that the finish markings that show the degree of

finish are different; they are explained in chapter

4.

This shows the tail. It is used to set off symbols

that order the machinist to use a certain process

or to follow certain specifications or other

references; in this case, specification A-1. The

tail will be omitted if it is not needed for this

purpose.

This shows the specifications, process, or other

reference explained in item 7. In this example,

the tail of the symbol indicates the abbreviation

of a process-oxyacetylene welding (OAW).

(The abbreviation standards for every welding

process are beyond the scope of this manual and

have been omitted.)

Figure 7-5 illustrates the various welding symbols

and their application.

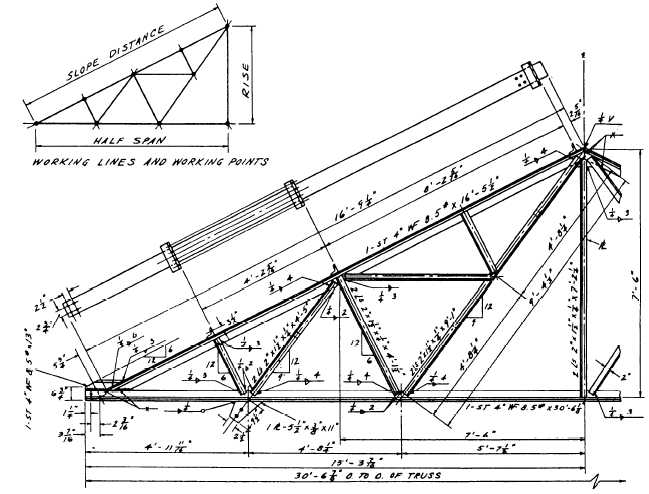

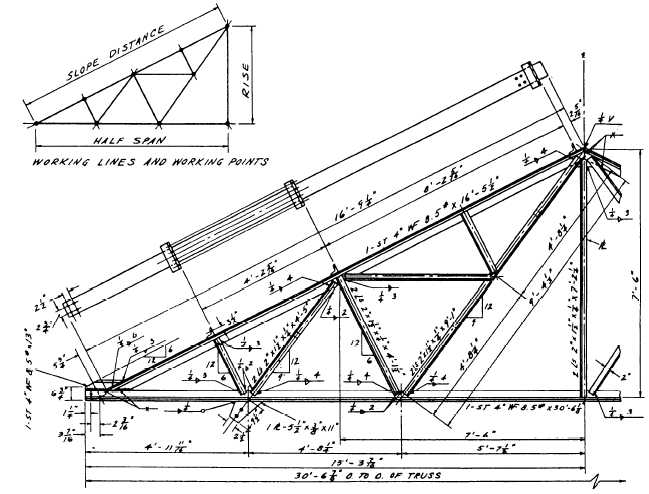

WELDED STEEL TRUSSES

Figure 7-6 is a drawing of a typical welded steel

truss. When you interpret the welding symbols, you will

see that most of them show that the structural angles will

be fillet welded. The fillet will have a 1/4-inch radius

(thickness) on both sides and will run along the angle

for 4 inches.

RIVETED STEEL STRUCTURES

Steel structural members are riveted in the shop

where they are fabricated to the extent allowed by

shipping conditions. During fabrication, all rivet holes

are punched or drilled whether the rivets are to be driven

in the field or in the shop.

Figure 7-6.—Welded steel truss.

7-7