Tolerances, Continued

Basic shaft

The basic shaft system is a system of fits in which the design size of the shaft

system

is the basic size and the allowance applies to the hole.

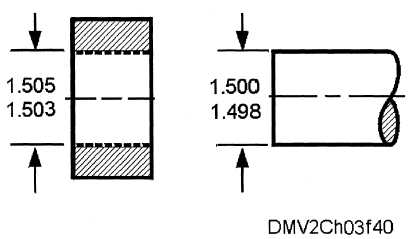

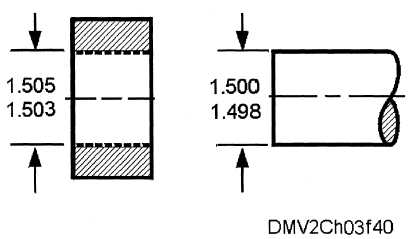

Figure 3-40 illustrates the basic shaft system.

Figure 3-40.—The basic shaft system.

In the illustration, the maximum shaft size is the basic size. To obtain the

minimum hole diameter, assume an allowance of .003 inch and add that to

the basic shaft size.

Arbitrarily selecting a tolerance of .002 inch, add the tolerance to the hole

and shaft to obtain the maximum hole (1.505 inches) and the minimum shaft

(1.498 inches). The clearance fit is the difference between the smallest hole

(1.503 inches) and the largest shaft (1.500 inches) or .003 inch. The

maximum clearance fit is the difference between the largest hole (1.505

inches) and the smallest shaft (1.498 inches) or .007 inches.

Determine the minimum hole size of an interference fit by subtracting the

allowance (.003 inch) from the basic shaft size (1.500 inches) or 1.497

inches).

To convert basic shaft size to basic hole size, add the allowance for a

clearance fit or subtract it for an interference fit.

3-45