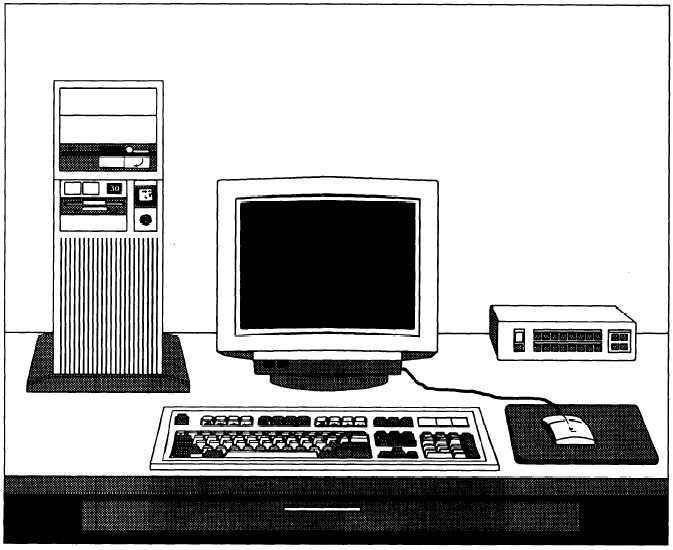

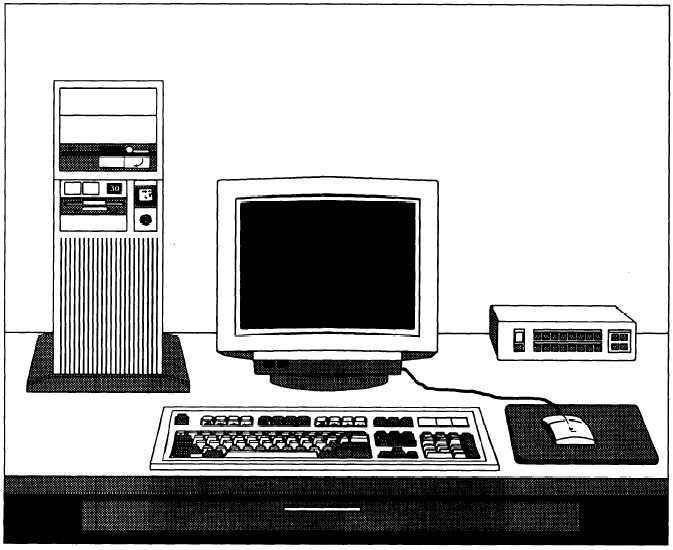

Figure 2-19.—CNC programming station.

In CNC, the machinist begins with a blueprint, other

drawing, or sample of the part to be made. Then he or

she uses a keyboard, mouse, digitizer, and/or light pen

to define the geometry of the part to the computer. The

image appears on the computer screen where the ma-

chinist edits and proofs the design. When satisfied, the

machinist instructs the computer to analyze the geome-

try of the part and calculate the tool paths that will be

required to machine the part. Each tool path is translated

into a detailed sequence of the machine axes movement

commands the machine needs to produce the part.

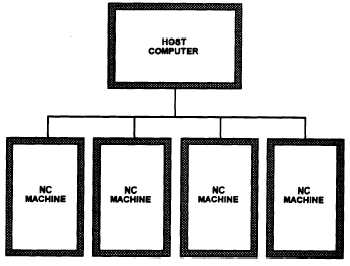

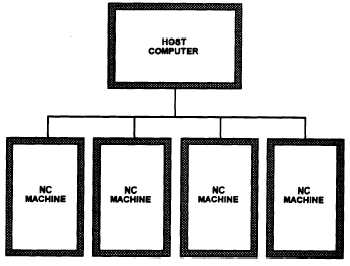

The computer-generated instructions can be

stored in a central computer’s memory, or on a disk,

for direct transfer to one or more CNC machine tools

that will make the parts. This is known as direct

numerical control (DNC). Figure 2-20 shows a

Figure 2-20.—Direct numerical control station.

2-11